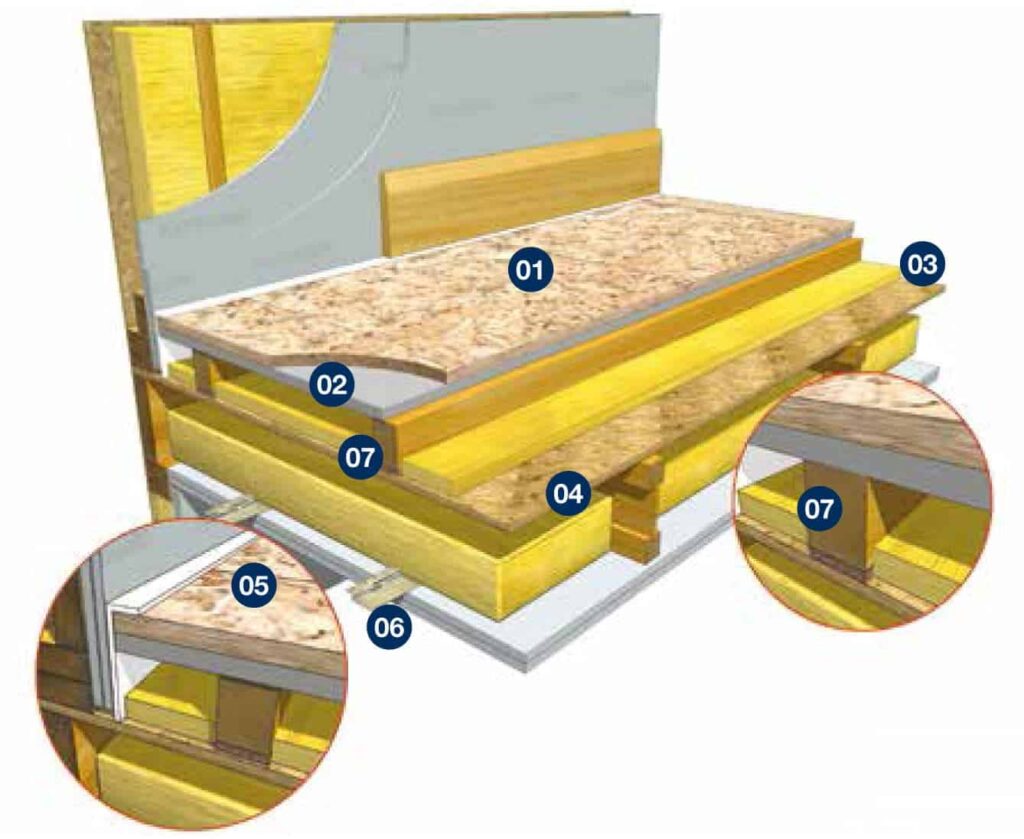

- 22mm (minimum) t&g flooring board – 600kg/3

- 19mm Plasterboard Plank

- 15mm OSB Board

- E-FT-7, E-FT-8 (UltraBEAM) floor types require Mineral Wool Quilt laid between the battens of: 50mm (minimum) 10-36 kg/m3

- JCW L Shaped or Flat Perimenter Edging Strip detail

- Resilient bars and 2 layers x 15mm Acoustic Plasterboard

- JCW 90T Acoustic Batten

Acoustic Batten 90T is ideal for timber FFT-1 Floating Floor Types: E-FT-7, E-FT-8 and E-FS-2

- Raised floor space can be used for installing services

- Ideal for good impact and airborne sound improvement

- Size: 90mm deep x 42mm x 1800mm

- Weight: 2.9 kgs

Reduction in Impact Sound Transmission: rd Δ Lw 16 dB

Improvement in Airborne Sound Insulation: 13 dB Rw + Ctr